BETTER THINK PINK

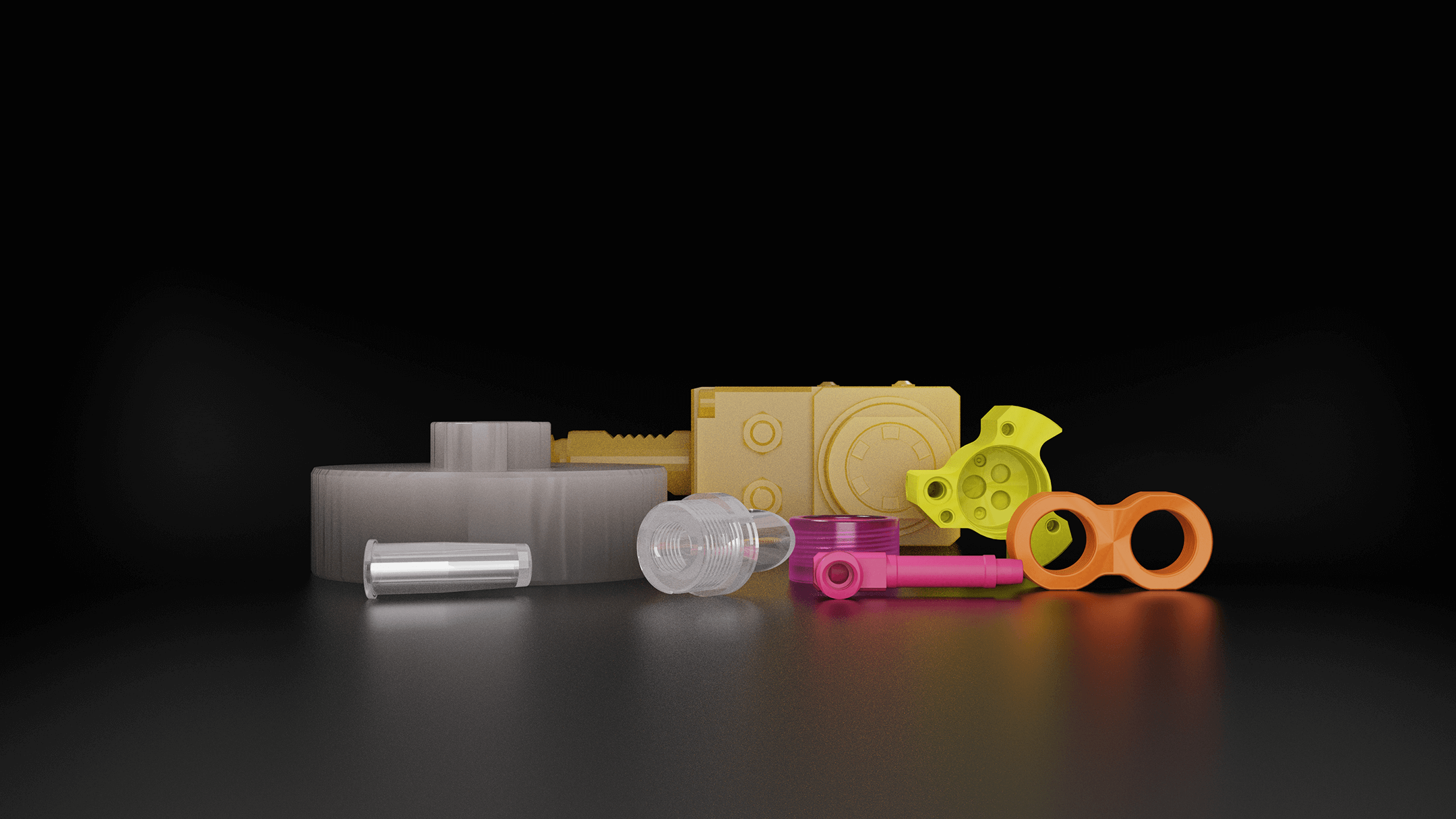

THE FUTURE OF PRECISION IS PINK

Precision is the only criterion for assessing the quality of a measurement. And it presupposes repeatability. This fact is the basis for the success of GROHE Technology. The repetition of the very highest precision. Workpiece by workpiece.

Turning technology

turning technology

All manner of precision turning. You decide.

When things become complicated and time-consuming, that’s when we get going. We produce precision parts of the highest quality on our modern CNC-controlled machinery. We can deliver medium or large series as quickly as possible thanks to innovative technology and optimal workflow. Of course, we also produce small runs and sample parts by prior arrangement..

Long or short?

Precision in series. No matter how big.

This demands the highest level of responsibility, care and expertise from each of us at GROHE Technology. Every day anew. Always precise, always on time and always with the passion for the art of machining that has always distinguished GROHE Technology.

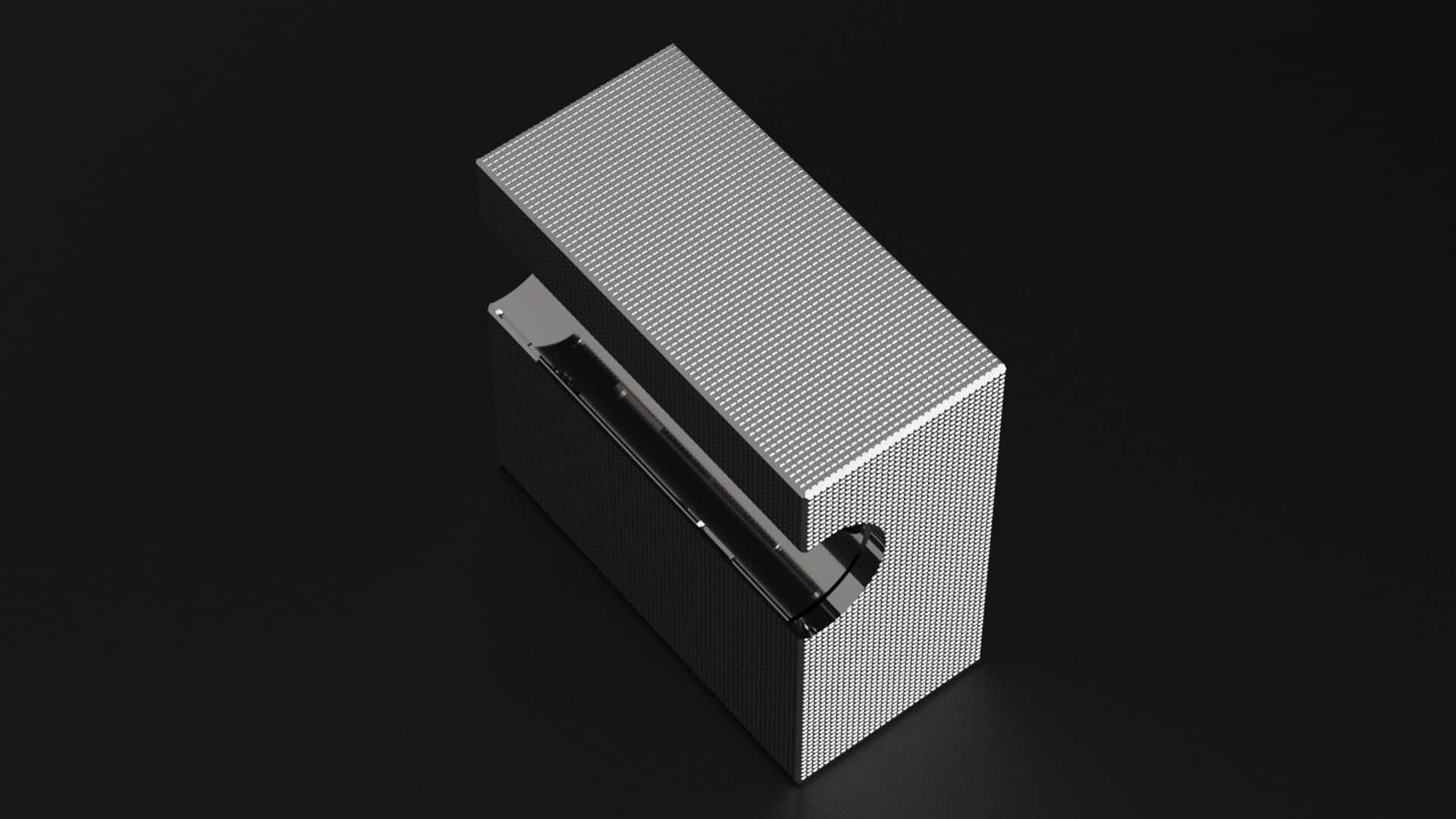

Precision in series

A feat in non-ferrous metal

For some, they are inconspicuous parts that only serve the function of a superior, far more important product. For us, they are the real heroes. Precision turned parts in a surface finish from Ra 0.25 µ. Burr-free, complex “off the shelf” machining solutions, in all copper-zinc alloys with an outer diameter of 8-65 mm.

More stunning resultsFrästechnologie

Frästechnologie

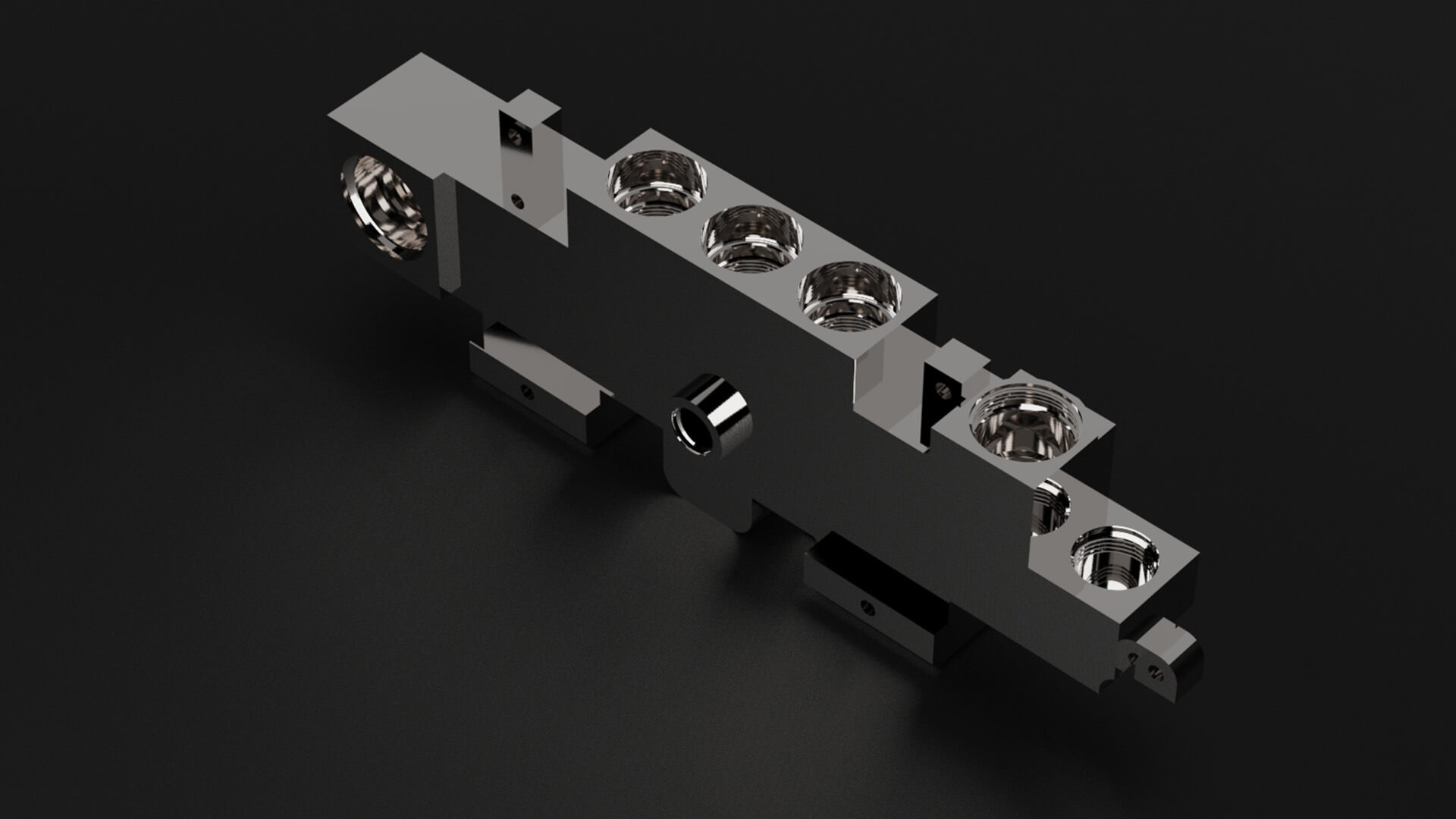

Fine milling from Ra 0,4 µ

Demanding workpieces? Lowest tolerances? State-of-the-art machinery with coordinated tools in conjunction with employees who undergo constant training, are a guarantee for first-class milling results.

Fine milling

5-axis simultaneous milling

Benefit from the enormous possibilities of 5-axis simultaneous milling. Our special experience in “path planning” – the simultaneous movements of the individual axes – promises optimum milling results with the lowest tolerances and perfect surfaces.

Optimum milling

Even the smallest series

Complex workpieces as prototypes or in small series? Gladly. We guide the spindle to the workpiece at almost any angle. In this way, even complex 3D contours become a reality in no time at all.

Quality in series

High gloss

technology

High gloss

technology

High gloss milling

If the surface of a 5-axis simultaneous machining is not glossy enough, we offer high gloss milling, a technology with which we achieve a high degree of gloss and image accuracy (RIQ, Reflected Image Quality). This is even shinier than any mirror surface.

More high gloss millingHigh gloss turning

We also call it “diamondising”. These beauties are created through dedication, skill and attention to detail. Because only when your workpieces look like jewellery will we deliver them to you. We achieve this with a special turning process that enables us to realise a mirror-like and high gloss surface quality without grinding and polishing. This means that the turned parts can be used for your desired surface without further processing.

More high gloss turning

3D printing

The future in parts production. 3D printing. What still applies to small series and prototypes today will soon become standard for medium and large series, too. GROHE Technology is well-prepared for this. With tomorrow’s expertise, today.

More 3D printing

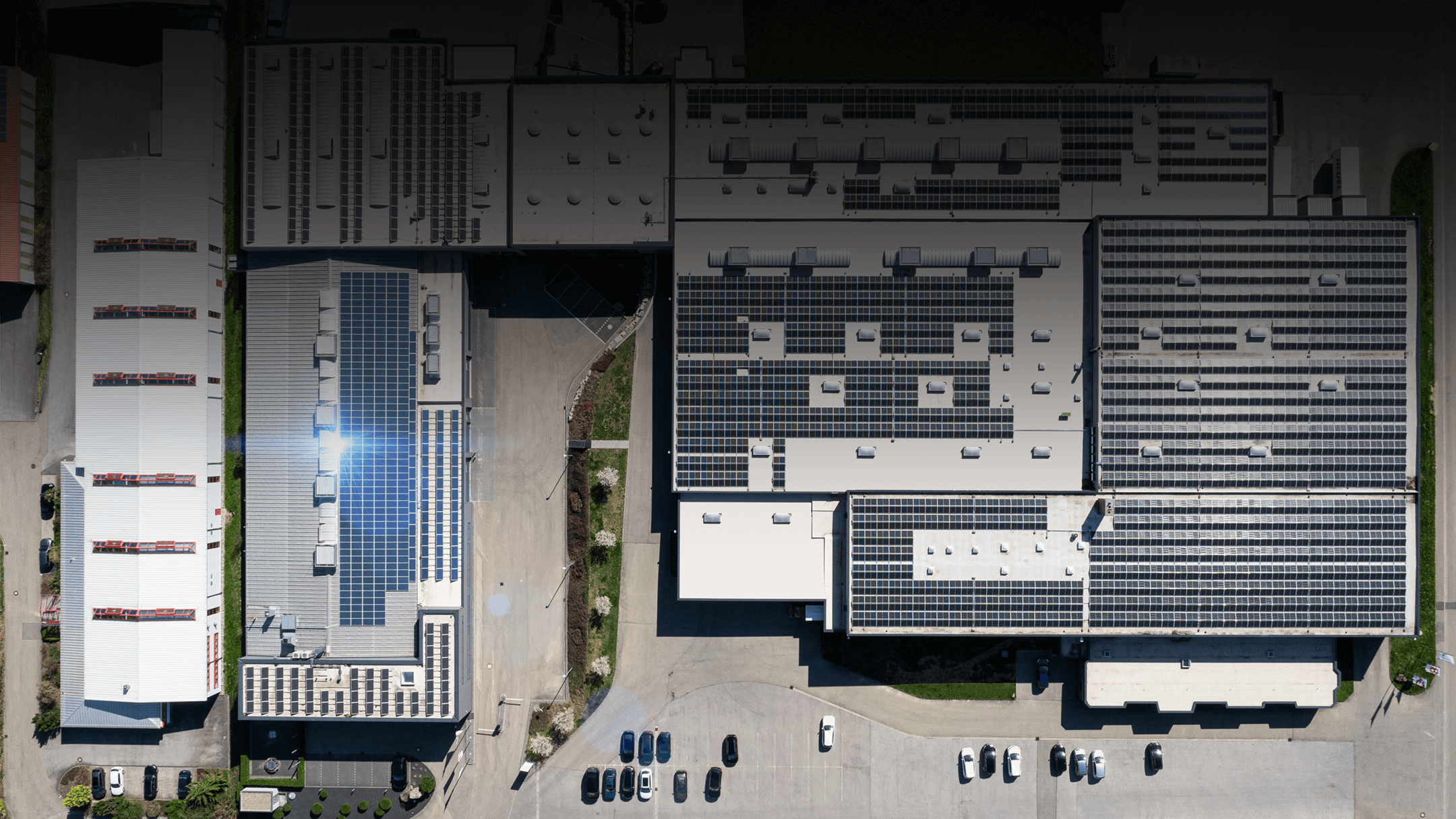

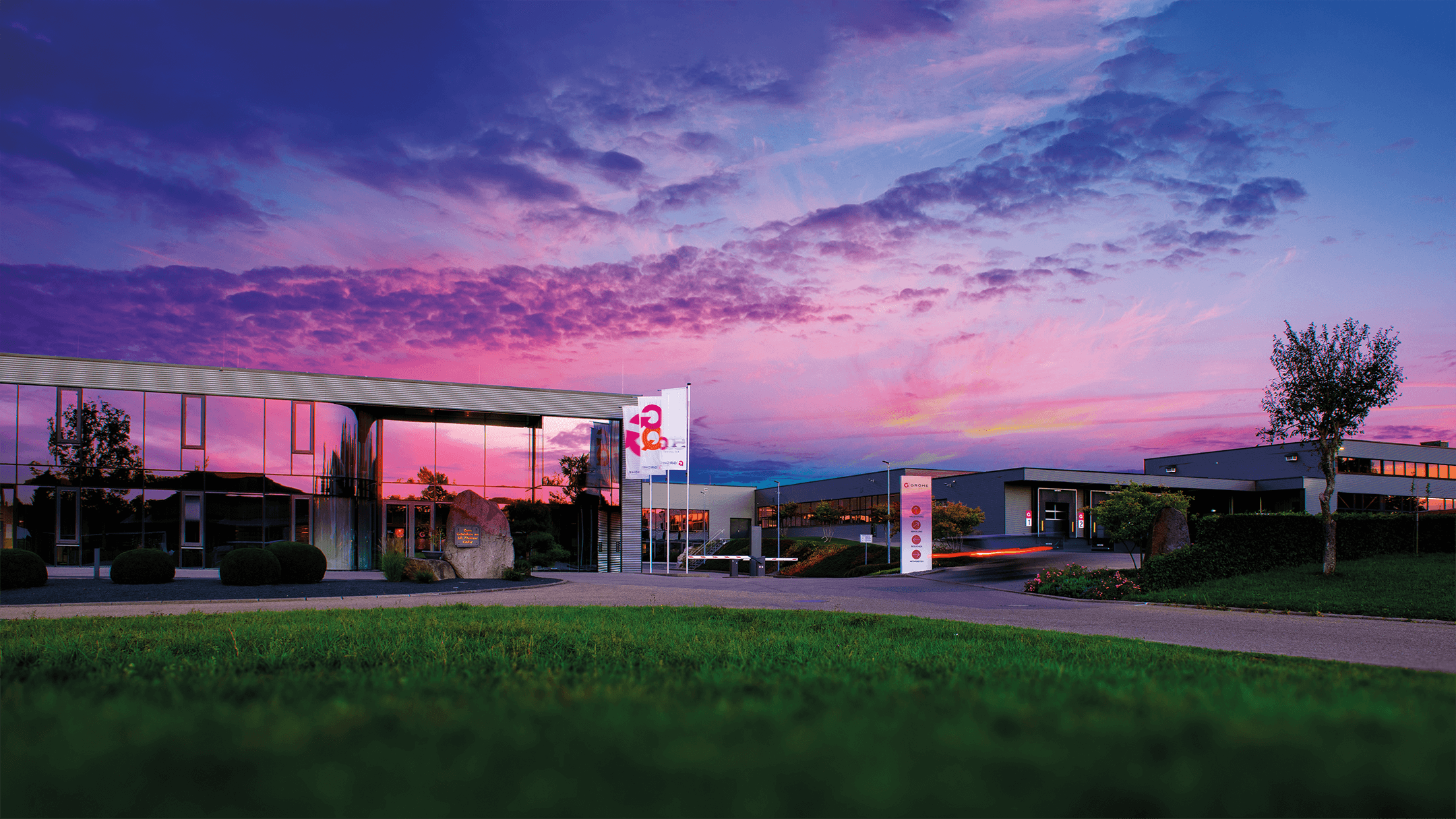

20.000 m²

of unbridled skill.

One of the most modern companies in the region produces more than 110,000 high-precision turned and milled parts every day. With highly trained employees who fully identify with GROHE Technology.

More about us

Welcome to our digital world.

Digital processes, networked logistics and a highly qualified team are our prerequisites for producing at the highest level. It’s best if you come and see it in person

Welcome

Modern. Effective. Highly productive.

GROHE Technology is at home wherever reliable high-end precision is required. In both large and small series. One precision part as exact as the next.

Precision

Machines. All cutting-edge.

We produce precision parts of the highest quality on our machinery. We can deliver medium and large series as quickly as possible thanks to the most innovative technology and optimal workflow. Small series and sample parts on request.

More news